Glen Report 34-17: New Product — Universal-CE Phosphoramidite

Cleavable linkers have been used in a wide range of applications and have been discussed in a recent Glen Report.1 We offer a range of linkers compatible with multiple cleavage methods, including enzymatic, hydrolysis, photolabile, and disulfide.

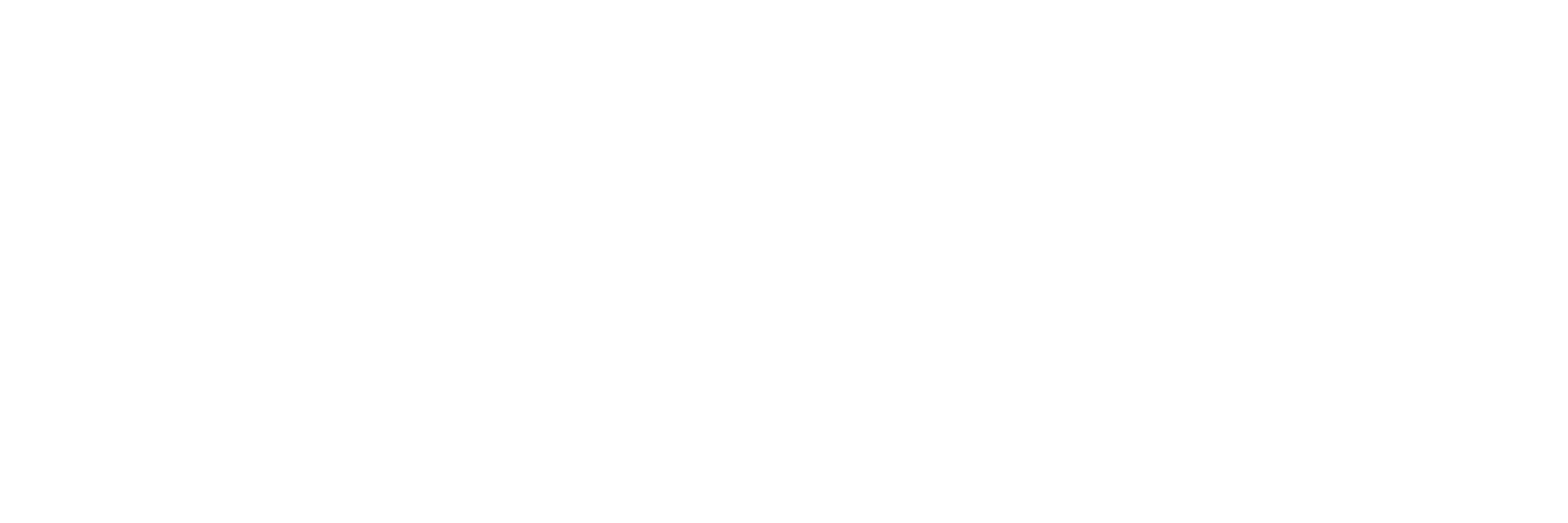

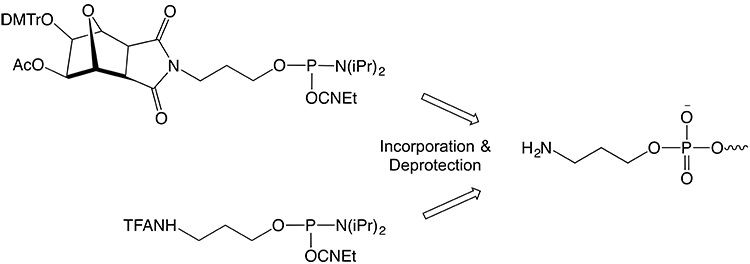

Among the cleavable linker products that can yield a strand break when incorporated in an oligonucleotide internally are PC linker and CPR (Chemical Phosphorylation Reagent). When incorporated, the cleavage of these two products leaves behind 5’- and 3’-phosphates.2,3 We are introducing Universal-CE phosphoramidite (10-5000), a new cleavable linker that yields two different end moieties, one bearing a 3’-OH and one bearing a 5’-amino modifier with a C3 linker, upon cleavage. The process of the cleavage reaction is illustrated below in Figure 1 alongside those of PC Linker and CPR.

Figure 1. Cleavage mechanisms of several products.

No phosphoramidite products in our current offerings directly yield a 3’-OH upon cleavage. Oligonucleotides with 3’-OH after cleavage may be crucial for certain downstream applications, such as primer extension or ligation assays. A few years ago, Universal-CE was used to remove truncated probe sequences from the full-length probes on in situ synthesized arrays.4 The process involved inverting the orientation of the probe in such a way that only the full-length probe was immobilized. Failure sequences incapable of probe inversion were removed from the system upon cleavage.

Based on the cleavage products, Universal-CE can also be used as a 5’-modification to yield an oligonucleotide with a 5’-amino modifier C3. The end product would be identical to if one used 5’-amino modifier C3-TFA (10-1923) (Figure 2). TFA amino modifiers are commonly used when oligonucleotide purification prior to conjugation is not required. In addition to not being compatible with reverse phase purification, modifiers with TFA groups are more susceptible to degradation during summer shipping.5 Universal-CE is a great substitute without the limitations of 5’-amino modifier C3-TFA. Universal-CE is a powder and easier to handle than an oil. When used as an amino modifier, Universal-CE requires less harsh conditions for deprotection. To release the amine, ammonium hydroxide overnight at 55 °C or 48 hours at room temperature or AMA, 10 minutes at 65 °C is sufficient.

Figure 2. Universal-CE as an amino modifier C3.

Universal-CE is based on the same chemistry as Glen UnySupport. Many of our customers are very familiar with UnySupport, which is compatible with multiple standard deprotection and cleavage conditions. Automated synthesis on a universal support has allowed unique modification at the 3’-end of an oligonucleotide. Universal-CE phosphoramidite could also be used to modify a hydroxyl- or amine-containing surface. This would create a universal-like support, capable of oligonucleotide synthesis and subsequent cleavage.

Synthesis & Deprotection

For coupling, no changes are needed from standard method recommended by synthesizer manufacturer.

For complete cleavage, deprotect using Ammonium Hydroxide:MethylAmine (AMA) 1:1 for 1 hour at 65 °C or Ammonium Hydroxide for 8 hours at 55 °C. For sensitive minor bases or dyes, use 50 mM Potassium Carbonate in Methanol for 17 hours at room temperature or with Tert-Butylamine/water 1:3 (v/v) for 4 hours at 60 °C.

References

- The Glen Report, 2021, 33.1, 6-8.

- The Glen Report, 2003, 16.2, 8-9.

- The Glen Report, 2011, 23.1, 10-11.

- W. Zhou, G. McGall, and V. Singh: February 2017, United States Patent, Centrillion Technology Holdings Corporation, PCT/US2016/047488.

- The Glen Report, 2013, 25.1, 11-12.

Product Information

- Glen Report 34-11: Beyond the UV Region — DEACM-dG as a Versatile Tool for Light-Activatable (“Caged”) Oligonucleotides

- Glen Report 34-12: New Product — DEACM Caged-dG

- Glen Report 34-13: Application Note: Phosphorodithioates in Oligonucleotide Therapeutics

- Glen Report 34-14: New Product — Ac-dC-5’-CE Phosphoramidite

- Glen Report 34-15: Purification of RNA Oligonucleotides (DMT-ON) using Glen-Pak DNA Purification Cartridges

- Glen Report 34-16: New Product — Palmitate Phosphoramidite

- Glen Report 34-17: New Product — Universal-CE Phosphoramidite

- Glen Report 34-18: Technical Snippets